Theresa Lorsch

23. January 2024

ABL eMobility Check: EV Battery Life

Everyone is talking about battery-powered driving. With the German government's goal of expanding the charging infrastructure throughout Germany by 2030 and further promoting the sale of electric cars, e-mobility is gradually becoming an integral part of its transport sector. Nevertheless, despite a high number of new registrations, EV batteries are still often met with scepticism: short lifetime, insufficient range, technologically immature. But how long do batteries really last? – The core component of every electric car in the ABL eMobility Check.

It's the inner values that count - how the battery's structure affects the range

In addition to the choice of manufacturer and model, range plays a key role when purchasing an electric car. It should be as long as possible, and charging should be fast and effective. One of the decisive factors for the range is the structure of the battery. In line with the modular principle, the battery consists of several modules, which in turn consist of a large number of cells. Chemical processes in the cells supply the energy required to power the car. The total capacity of the battery pack and the energy and power density are decisive for the range of the electric vehicle. Ergo: The more battery cells and the higher the energy density per cell, the greater the available energy. In addition to these factors, the cell format also influences the energy density and range. The cylindrical, prismatic and pouch formats are commonly used. The lithium-ion battery is currently the pioneer on the market.

According to the General German Automobile Club (ADAC) (2024), the range of current e-vehicles is currently between 150 and 610 kilometres. It should be noted, of course, that the range depends on many external factors (e. g. driving style, weather conditions) as well as the power consumption of the electric motor. Good to know: The range that can actually be achieved is therefore often lower than the value stated by car manufacturers (ADAC Ecotest).

What is the lifespan of an EV car battery?

In fact, a battery loses capacity over time through regular use. This process can be counteracted by taking a few simple measures:

- Avoid extreme temperature changes: Although the built-in battery management system (BMS) ensures that all processes in the battery are constantly monitored, it should not be exposed to extreme weather conditions.

- Driving style: Anticipatory driving at an appropriate speed prevents the battery from discharging quickly and thus from being subjected to a high load.

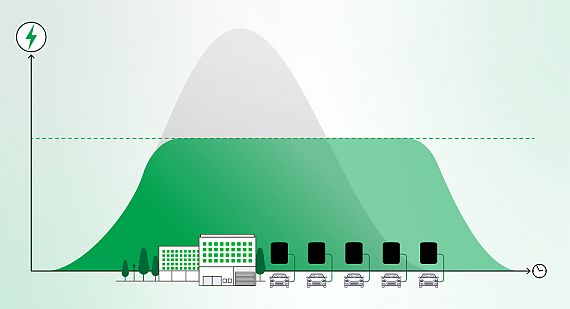

- Number and type of charging processes: Charging on AC chargers has proven to be more battery-friendly than charging on fast chargers (DC chargers). Therefore, the motto "less is more" also applies to charging - fewer charging cycles and a constant charge status in the medium range.

- Avoid non-use of the car:This is because processes in the battery lead to a reduction in battery capacity even when the electric car is stationary for a long period of time.

- Regular maintenance: An inspection at a specialist workshop can also extend the service life of the battery.

Maintenance and repair - Can a complete replacement be avoided in the event of damage?

The production of batteries for electric cars is expensive and energy intensive. Therefore: Repair instead of battery replacement! Although the transformation from battery disposal to battery repair has not yet been completed, the expansion of capacities and the transfer of the corresponding expertise is in full swing. Sustainability and resource conservation will be further emphasised by the EU Battery Regulation adopted in June 2023. The battery passport with further information on the product, for example, is intended to ensure greater transparency.

How does a battery repair work?

The first decisive factor is whether the vehicle manufacturer is able to repair a defective battery. An intensive analysis of the battery pack is followed by replacement of the affected modules. Moreover, it must be ensured that the voltage of the newly installed module matches that of the other modules.

Battery-powered driving – a futureproof solution?

If one wants to draw an overall conclusion about the battery as a drive technology, it can definitely be rated as forward-looking. Nevertheless, a number of technological, political and user-related challenges still need to be overcome. Efforts to reduce the greenhouse gas balance over the entire life cycle of a battery, to improve the range through new technologies and implement new recycling and reuse scenarios for disused batteries (e. g. as stationary storage for PV systems) will create a corresponding basis. A basis on which electromobility can build sustainably.

Submit comment

Relevant articles

YTo0OntpOjA7aTo0NjQzO2k6MTtpOjUyMTY7aToyO2k6NTE5OTtpOjM7aTo1MTgwO30=

94

czoyOiIzNSI7